Scanning and Fault Diagnosis. In contemporary motor vehicles, engine controls, gear controls, brake controls, suspension controls, active and passive safety systems are designed to maintenance of high emission control standards, high fuel efficiency, driving comfort and to ensure the safety of passengers and pedestrians. These are designed to operate electronic control circuits in such a way that they can operate at their maximum optimization limits logically and accurately.

Therefore, sensors equipped with physical systems such as operating temperature, velocity, position, touch and flow, which are unique to each of these systems, and control units that make logical and bilateral, operating devices that control these decisions, the correct operation of all electrical circuits which maintain connections between the units may increase or decrease the quality and efficiency. It also reduces the safety of the roads.

In the long term run, the sensors do not work as well, and the mechanical wear and tear on friction, increase of the temperature, factors such as short and open electrical circuits, the performance of these sensors and operating devices may be impaired as well as even software applications on computers are also likely to modification.

Each electronic control system is therefore designed to self-diagnose all of its integrated functions so as to avoid the potential danger of exponential inaccuracy. In this event, the error control system will be activated by a malfunctioning light indicator on the system meter panel that identifies the driver and activate the system for Secure backup or enable fail- safe control function.

However, some mechanical faults may not be detected simultaneously by the computer system, and there may be instances where the nearest operating system is detected by the auto-error monitoring system. It is also possible that several systems may be defective, depending on the error status of one system and the impact on another system running parallel to it.

If a defective vehicle is to be inspected for faults in these systems, it must be tested by a technician who is well versed in operating the system, has a logical understanding of fault detection, and is trained well in theoretical and practical matters.

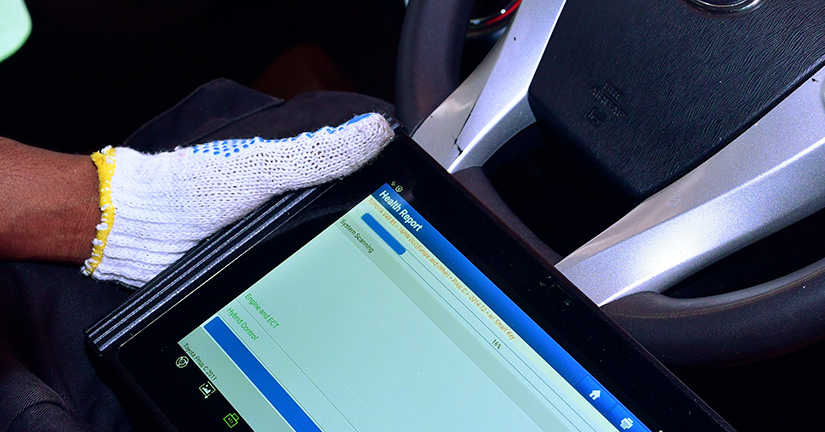

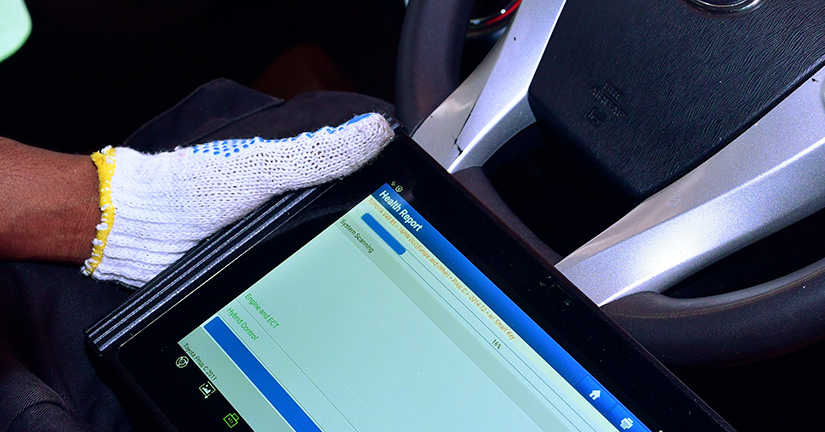

It is also important for an automobile technician to be able to analyze real time data and identify the error by using logical intelligence, but just not scanning tools with the latest OEM software based error codes of the scanning device. This is because of the lifespan of your vehicle, the cost of repairs, and the time it takes to repair the defects and repairs that need to be done.

This service provided by our company is always concerned with the use of up-to-date scanning equipment and technicians who are specialized in this service and save you money and time by making the customer aware of the repairs that need to be done at once without any hassle.