Inverter and Radiator Cooling System Maintenance. The main components of the first and second chapters of the hybrid vehicle, such as the hybrid battery, the power inverter, the hybrid transmission and the internal combustion engine, must all be maintained at the specified temperature range for maximum efficiency. The cooling systems thus designed may be of two types.

Classified as follows;

1. The active cooling system

2. The passive cooling system

Depending on the design of the car, one of the two methods used by the manufacturer is to create cooling circuits for each of them, either individually or individually.

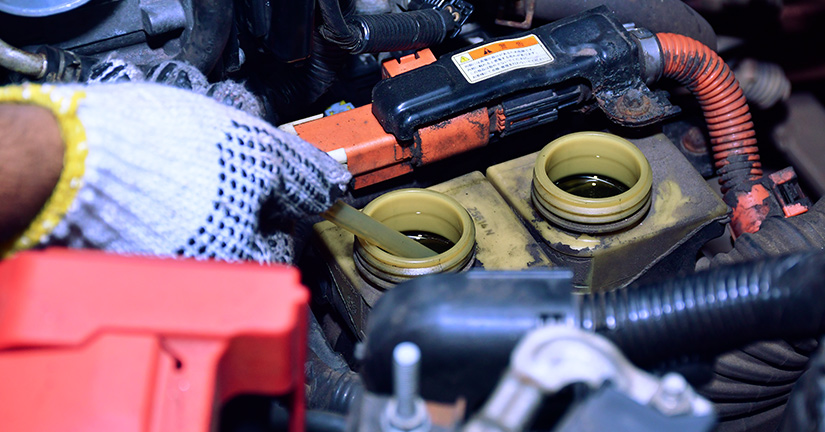

The power inverter unit, often referred to as the brain of the engine and hybrid system, is an active cooling system that is often designed using a hydraulic cooler to meet the cooling needs of these systems.

The coolant used here is chemically designed to operate on the same system, the inverter coolant is called the inverter coolant, and the engine cooler is called the radiator coolant.

These are special anti-rust, anti-nitrate, anti-phosphate, anti-borate, etc. chemicals with special properties. They therefore vary from system to system depending on the nature of the cooling system, the design, the cooling range and the absorption of heat. Also, their original properties change due to chemical changes that occur during operation, which have a serious effect on the cooling units. As with the engine oil in the car, the coolant has to be changed again depending on the environment, time and driving distance of the vehicle.

This is stated by the manufacturer in the vehicle specific service manual and it is recommended that the coolant be changed first on the basis of the driving distance and the time of arrival. Many complex electronic circuits, such as the power inverter, are integrated into one unit, causing the hybrid system to overheat rapidly as operating speed and load limits increase, in which case.

these circuits overheat and require active temperature control to maintain the same function or not. Destructed and re-applied at a high cost. The coolant passes through the cooling tubes created between them.

The coolant used depends on the chemical compounds used in their design and classified into three categories.

IAT: Inorganic Acid Technology

IAT is the traditional green stuff that is pretty much only used on older cars that predate the late nineties. The lifespan of traditional coolant is about two years.

OAT: = Organic Acid Technology

OAT is used today because it offers silicate-free protection of all metals, and for a longer period of time: it’s the long life (LLC) or extended life (ELC) coolant and has a service life of five years or 150,000 miles. Colours are mostly red and orange, but also green, pink and blue.

HOAT: = Hybrid Organic Acid Technology

This is also used today, and is usually orange or yellow. A mix of IAT and OAT, the orange cocktail – and only the orange -- contains 10 percent recycled coolant.

In order to distinguish these from each other, the above is given a unique colour. Therefore, it is important to pay attention to the original colour of the cooler when replacing it. Therefore, the technician should pay attention when replacing the cooler in service and their type and always make sure to use only the approved cooler. And not using the correct types.

Our company uses state-of-the-art equipment to check the quality of the coolant in each service and to recommend and use only the essential coolant quality approved by the manufacturer. Not only in hybrid cars, but also in modern car engines, temperature control is controlled by computer programs using an electronic speed control water pump. This minimizes the engine power loss caused by the water pump with the drive belt and the temperature control difficulties associated with the up and down speed of the engine and allows the temperature to be adjusted quickly and successfully.

Depending on the design of the cooling system of the typical car and the type of coolant used and the environmental conditions under which the vehicle is driven, the cooler replacement time varies and is generally considered to be in line with the driving conditions in our country. It should be serviced on a first-come, first-served basis after every 30,000 km or six months of quality testing.